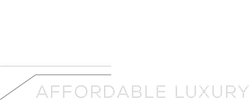

Most manufacturers cut costs by using plywood as a core and as a backer substrate to carry the face layer. Our planks have a superior solid hardwood lumber construction.

Plywood by itself is a stable product. It is made up of many thin layer of wood cross glued in the opposite direction of the grain. The idea behind it is to create a wood which expands in the width as much as in the length, but all other woods expand in the width 10 times as much as in the length.

By using a stable product, plywood, and adding a face layer of wood which wants to expand 10 times as much in width as in the length you are creating an unstable product again.

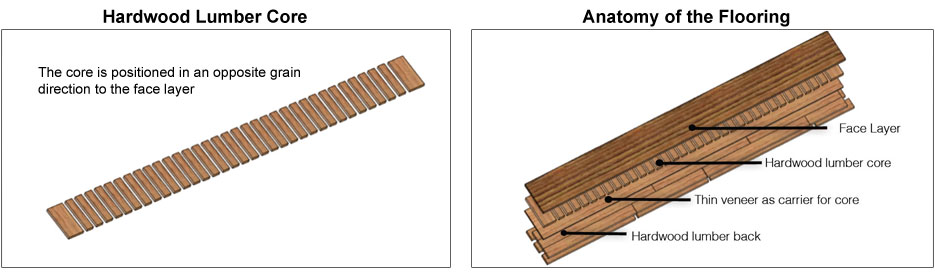

Using our solid hardwood lumber core glued into the opposite direction of the face layer, and adding a solid sawn back, again in opposite grain direction, we are limiting the shrinking and expanding of your floor to a minimum.

You might not see a difference when you compare individual pieces of these two construction types, but when your floor is installed and there is a change in humidity, you will see less movement with our solid hardwood lumber core and back.